Product detail

As you may have read in other places of our store, Sakai Takayuki is one of the top manufacturers of kitchen knives. It has gained this status thanks to great craftsmen who represent the absolute top not only in the Sakai area, but throughout Japan. Of course, the first violin in this orchestra is played by the blacksmith, followed in close succession by the grinder. These are absolutely key posts that decide success or disappointment. Sakai Takayuki has absolute virtuosos in both positions. But judge for yourself.

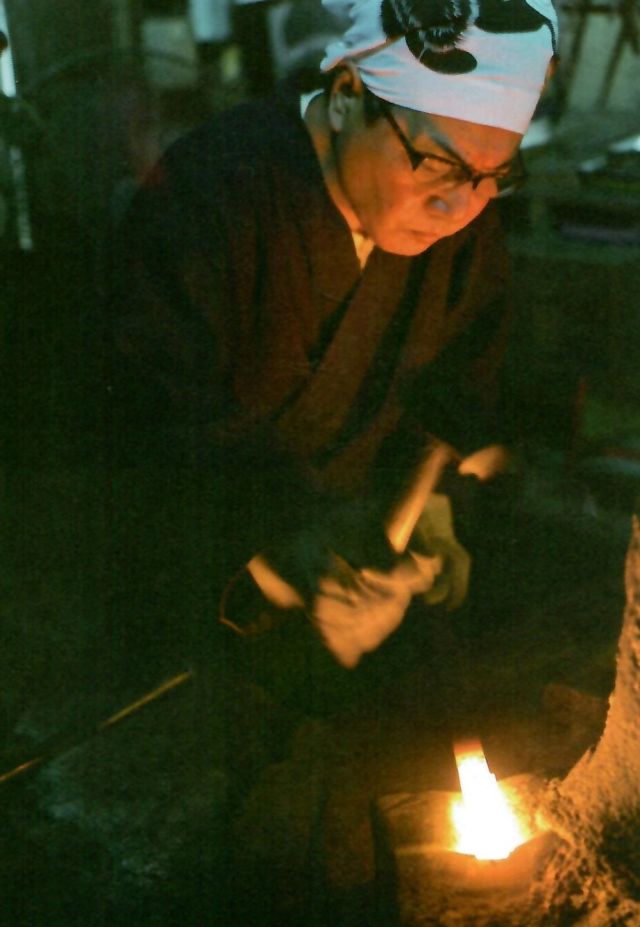

Itsuo Doi is the third generation of the blacksmith clan. He continues the work of his grandfather Kazuo and his father Keijiro. His favorite material is Hitachi Metals' "blue" Aogami steel. Seeing this master transform a small piece of profiled steel into a blade is a real experience. In his workshop, you will also find a young blacksmith, who initially performs less demanding tasks, but Doi-san gradually draws him into the plot and thus prepares his follower.

A properly forged blade is an absolute foundation. But it lacks functionality. This is delivered by Mitsuo Yamatsuka. Everyone wants a blade from him. And that is a serious problem. This operation is more complicated than it seems at first glance. This is where the most significant time "funnel" arises in the entire production process. Delivery times exceeding one year are therefore understandable. Yamatsuka-san is aware of this and that is why his two sons and a daughter work in his workshop. After all, who is better to rely on than one's own blood?

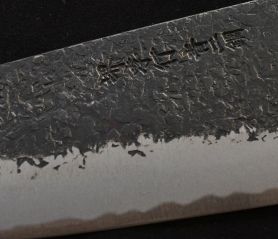

The Homura series is reserved for traditionally hand-forged blades with a symmetrical, double-sided profiled blade. Authored exclusively by Doi-san and Yamatsuka-san, this is the best of the segment. The San-Mai blade is really massive and will get you with its texture. It is not the classic Tsuchime we are used to, nor the delicate Nishiji. It's a rather complicated texture at first glance reminiscent of kanji characters lying around. The depth of this "pattern" gradually decreases towards the edge. It is the work of the master hammer who left it in Kurouchi modification. Its black passes through the dull gray shinogi into the polished hamon. The core is forged from Aogami 2. The master does not waste time by forging the mark. It's his assistant's job. On the left side, he hand stamped the name of the company and the material (Sakai Takayuki, Blue 2), on the right the blacksmith's personal emblem and Homura's name, of course all in kanji characters. Yamatsuka-san conjured a masterful Hamaguri with an almost invisible facet. Despite the robustness of the blade, its sharpness is exemplary.

This Homura series was given the nickname Guren. It is a term for naming a red water lotos. Apparently due to the color similarity with the oak handles. They have the shape of an octagon and a tanned lower part. This increased not only the aesthetic value, but also the resistance to moisture. The absence of a ferrule is more than welcome in this case. The packaging corresponds to the overall concept. In addition to various tastefully presented information, you can also find small origami here. Carefully unfold it and you will find a nice gift inside. Which one, we'll keep that to ourselves.

In conclusion, just a statement: take the finest traditional materials, call the biggest names in the field and let them handcraft a kitchen knife = Homura Guren.

©2023 Copyright Roman Ulík, Nippon Knives, www.japonskenoze.sk all rights reserved.

Photos and texts are protected by copyright law and their use without the author's consent is not possible.

About producer

Sword – a symbol of ancient Japan. It is no coincidence that it forms one of the imperial insignia. It is a Kusanagi sword and its core was also created by multiple folding and forging of the highest quality steel. Thanks to many generations of talented craftsmen, this proven method of producing hard and tough material has been preserved to this day. This is how knives were created that have no parallel in the world.

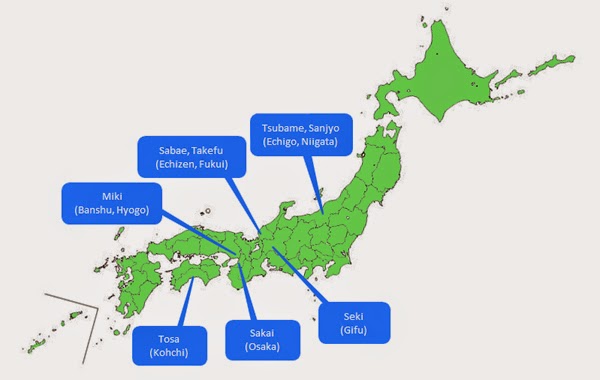

Sakai, or the city of knives, is today a western suburb of Osaka. The city experienced its greatest development in the 16th century, when it was one of the busiest commercial centers. The latest technologies from all over the world as well as different cultures met here. This helped the development of blacksmithing techniques, which had already reached a high level thanks to the production of traditional swords. The Portuguese brought the first rifles to the area and Sakai blacksmiths changed the production program. But since it was a period of peace, they mainly produced decorative rifles. With the boom in tobacco, they smoothly transitioned to the production of knives for cutting tobacco, but the mechanization of its processing resulted in another production change. Blacksmiths began to specialize in the production of kitchen knives. It was also influenced by the proximity of another important city - Kyoto. It is characterized by its culinary art, and the preparation of individual dishes requires special knives. Today, the majority of Japanese chefs use knives made in the city of Sakai.

Sakai has a slightly shorter history compared to Seki, but nowadays it is their meaning comparable. The difference is mainly in the production program. In Seki, the production of Western-style Japanese knives prevails, with a strong emphasis on export. Manufacturers in Sakai, on the other hand, specialize mainly in traditional Eastern-type knives. Their clientele consists mainly of Japanese professional chefs.

Mr. Takayuki became famous for consolidating the Sakai blacksmiths in 1946. He provided them with production facilities and tools and thus founded the Sakai Takayuki brand. It is currently being looked after by the 3rd generation of this family. The brand is owned by Aoki Hamono, which in 2006 won the prestigious Sakai Wazashu award for the skill of local manufacturers.

The potential of the Aoki Hamono company lies in key personnel positions, which are blacksmith and grinder. Masters with high awards and with experience exceeding 50 years in some cases work here.

Keijiro Doi - blacksmith

At the age of 19, he took the place of his father, a prominent blacksmith, in the workshop. In 1987, he was certified by the Ministry of International Trade and Industry as a Blacksmith Master. In 1997, he received the Green Paulownia Leaves award.

Yukinori Oda – grinder

He is a holder of the Sacred Treasure order, Silver Rays. Already at the age of 20, he became a master. He sticks to his motto: "The sharpness of a good knife is 100%." However, the role of the grinder is to increase it to 120%."

Suogo Yamatsuka - blacksmith

He constantly pushes the boundaries of perfection. He specializes in Gingami 3 anti-corrosion steel.

Hirotsugu Tosa – grinder

He was born in 1948 and trained as a grinder at the age of 18. In 1991 he achieved the title Sharpener Master. He knows no compromises in his work because he is constantly thinking about the users of his knives.

Itso Doi - Blacksmith

Son of Master Keijiro. It represents the third generation of the clan. He is best placed to preserve this championship for generations to come.

Mitsuo Yamatsuka – grinder

In 1999, he received the Japanese Traditional Craftmanship certificate. It is a guarantee that a traditionally forged knife will acquire "Sakai" sharpness.

Due to the handmade production and the huge interest among professionals in Sakai knives, it is quite difficult to obtain at least a few pieces. Our efforts and patience finally brought us the honor of introducing you to products in which the soul of their makers resides. Welcome to Sakai!

Video from the workshop

©2019 Copyright Roman Ulík, Nippon Knives, www.japonskenoze.sk all rights reserved.

Photos and texts are protected by copyright law and their use without the author's consent is not possible.

Sign in

Sign in Registration

Registration