Sakon+

Coating is not a revolutionary technology these days. But the patented Vee-Tech process used in the aerospace industry is a completely different league. The result is a perfect fusion of materials, where there is no risk of unwanted separation. In this way, a narrow layer of ultra-hard carbide, incidentally again "borrowed" from the aerospace industry, was applied to one side of the steel blade. Carbide forms micron protrusions forming invisible teeth. Compared to carbide, steel is a soft material and naturally wears out during cutting. The more you cut, the more carbide "teeth" are exposed and the sharper the knife. And here's an explanation of the rat tooth designation.

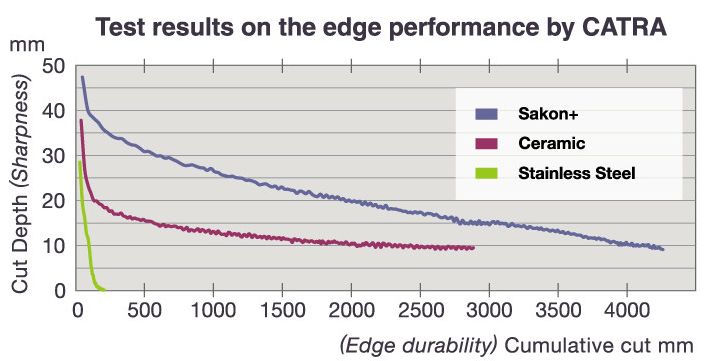

The carbide is a fine material with exceptional resistance to mechanical

and heat load and therefore it is widely used in spacecraft construction. But let's go back to the knives. The renowned British testing laboratory CATRA confirmed with its test that the decrease in sharpness of SAKON + blades is many times slower than with conventional steel knives and even slower than with ceramic knives.

According to the manufacturer, in accordance with the usual principles of using quality knives, it is not necessary to grind the SAKON + blade throughout the year during daily home slicing. We can confirm this fact from our own experience. We take the results of CATRA, which are always accepted by the professional community, with full seriousness.

and heat load and therefore it is widely used in spacecraft construction. But let's go back to the knives. The renowned British testing laboratory CATRA confirmed with its test that the decrease in sharpness of SAKON + blades is many times slower than with conventional steel knives and even slower than with ceramic knives.

According to the manufacturer, in accordance with the usual principles of using quality knives, it is not necessary to grind the SAKON + blade throughout the year during daily home slicing. We can confirm this fact from our own experience. We take the results of CATRA, which are always accepted by the professional community, with full seriousness.

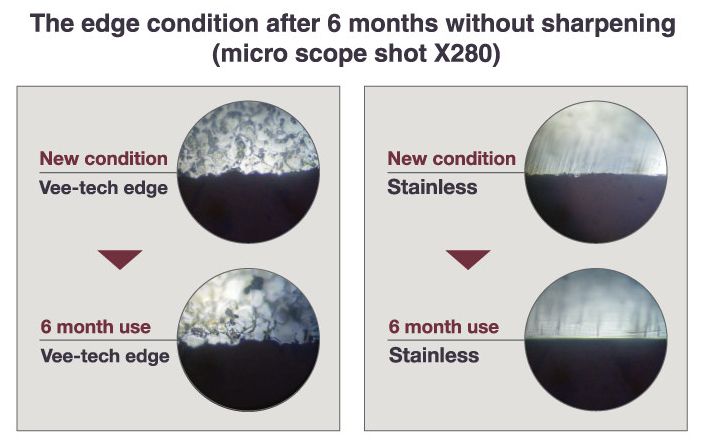

The result of Vee-Tech's patented technology is the creation of an alloy of carbide with steel. For the best understanding of the rat tooth principle, a microscopic view of the blade edge after 6 months of use without grinding is used. If the Vee-Tech blade obviously has larger "teeth" for better cutting, the normal steel blade is without any protrusions, ie without the ability to cut. I'm sure you're asking, "What about a year?" The charm of the Vee-Tech blade is that you can normally sharpen a knife on grinding stones, of course on the steel side, not the carbide side.

It is logical that such revolutionary blades should not be combined with ordinary wooden handles. The choice therefore fell on the methacrylic resin known as synthetic marble. This material is free of pores and due to its excellent antibacterial and antifungal properties, it is also used for the production of kitchen sinks and worktops. Great emphasis was placed on exemplary ergonomics. The deep and rich transparency of the resin creates an elegant "cool" beauty. This is further enhanced by the contrasting black and white combination.

You can get SAKON + in three practical versions. In addition to the popular multifunctional santoku knife, it is a universal petty knife and chef knife.

https://www.youtube.com/watch?v=8NOGf7eI9-E

©2010-2018 Copyright Roman Ulík, Nippon Knives, www.japonskenoze.sk,all rights reserved.

Photographs and texts are protected by copyright and their use is not possible without the author's consent.

Sign in

Sign in Registration

Registration