YOSHIDA HAMONO

ZDP-189 is Hitachi Metals' ultra-hard steel. It was developed at its Yasugi Specialty Steel center by powder metallurgy with priority for cutting tools. It therefore has very small carbon carbides, which provide the blades with excellent abrasion resistance. It is not a high speed steel / HSS / such as SKD-11 or SRS-15 , but thanks to the 3% carbon content, it reaches a hardness of up to 67 HRC when processed correctly!

Such a high carbon content also requires proper supply of chromium to prevent rapid oxidation. 20% of this element makes ZDP-189 steel with increased corrosion resistance. Therefore, the knives do not need to be treated with oil. In addition to the two elements mentioned, steel is alloyed with tungsten, vanadium, molybdenum, manganese and silicon. It owes its astonishing hardness not only to its chemical composition, but also to its hardening in cryochambers - sub-zero treating . The heated material is quenched with liquid nitrogen to -196 degrees Celsius.

Working with such hard material is very difficult and expensive. It requires a lot of experience and a specially equipped workshop. ZDP-189 is used, for example, by the Japanese iconic pocket knife manufacturer Rockstead or the Miyabi brand, which processes it to a hardness of 66 HRC. In both cases, however, it is machine production.

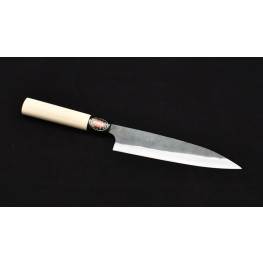

Yoshida Hamono prepares layered materials from the basic components: ZDP-189, stainless steel and nickel. In addition to the price, manual labor also requires time, so delivery times of about a year are not surprising. Precise hardening and tempering achieve the exceptional properties of this extraordinary steel.Extremely hard blades also require proper handling. They certainly do not belong in the hands of beginners. Bones and frozen products are an absolute taboo. It is recommended to cut only on wooden boards, in no case on hard surfaces. However, the rewards will be the fine cut, blade durability and artistic value of this ultimate tool.

The Kyusakichi knives we bring you from Yoshida Hamono are referred to as Wa-Bocho - Japanese knives. These are characterized by a half tang construction, where the glowing tang of the blade is punched through the ferrule into the handle. To make the knives as versatile as possible, the handles have an octagonal shape that is equally suitable for both right-handers and left-handers. We are already used to them with quality knives, but their material is a novelty for us. Japan has acceded to the Washington Convention (CITES) on International Trade in Endangered Species of Wild Fauna and Flora. This means that exotic woods are gradually replaced by materials that are very aesthetic, much more durable and do not endanger any biotopes. They can be made on the basis of resins / Micarta /, acrylates / Corian /, or wood / Pakka , Kebony /.

Kyusakichi knife handles are made not only of rosewood but also of impregnated maple, which is a product of the Norwegian company Kebony. Wood maple is impregnated with a bio-sugar solution. The cell walls are strengthened by up to 50% and hard and durable wood is produced. Its hardness of 41HB significantly exceeds the hardness of teak / 34 HB /. This is ecological and harmless wood. Its texture resembles a rosewood. Over time, it changes color to silver-gray, which gives it an interesting patina. This process can be slowed down by oiling the handle.

2020 Copyright Roman Ulík, Nippon Knives www.japonskenoze.sk all rights reserved.

Photos and texts are protected by copyright and their use is not possible without the consent of the author.

-

Ko Bocho KU-1

On stock65,00 €Ajikiri KU-2

On stock65,00 €Ajikiri KU-2 On stock70,00 €Funayuki KU-3

On stock70,00 €Funayuki KU-3 On stock80,00 €Nakiri KU-4 vegetable knife

On stock80,00 €Nakiri KU-4 vegetable knife On stock80,00 € 80,00 €Yanagi KU-5 - slicer

On stock80,00 € 80,00 €Yanagi KU-5 - slicer On stock80,00 €Our partners

On stock80,00 €Our partners

© Nippon Knives 2024, created by vibration.sk

Sign in

Sign in Registration

Registration