Where Tamahagane is born

The concept of Tamahagane creates insights for Japanese swords made of the most perfect steel. After all, the literal translation of the term tamahagane is precious steel. To this day, it is produced in Japan in the traditional way twice a year. However, we are going to focus on knives bearing this proud name. They have been on offer at the Nippon Knives store for several years and experience confirms that they make the name Tamahagane the bst statu.

The journey to the birthplace of Tamahagane knives begins in Tokyo. Yuji, a tall, athletic man in his fifties is waiting for me at the reception of my hotel 10 minutes before the scheduled date. This is just so that I do not forget that in Japan, accuracy comes first, closely followed by decency, order and organization. We take the subway to the headquarters of their company in the very center of Tokyo. After all, only a madman would try a taxi. Just don't get into a woman's car anymore, as I've already did. Founded in 1869, the company has its headquarters in Chiyoda, opposite the Imperial Palace. It also included the export of knives brands of Tamahagane in its rich business activities. In Japan, there are many manufacturers who are dedicated exclusively to production and sales are taken care of by external companies or associations. In contrast, brands like Kasumi , Tojiro >, Mcusta Zanmai , Masahiro , Sakon , Global and others are exported by their manufacturers.

With a cup of traditional tea, we plan a trip to the Kataoka factory. Its owner, Kataoka-san, belongs to the third generation of the clan. It is he who is behind the birth of the Tamahagan knives. Its headquarters are in the town of Tsubame in Niigata Prefecture, which is located in the northern part of the main island of Honshu. We will travel by train from Tokio Station, so I suggest a meeting right there. But Yuji assertively decided that he would rather come to my hotel again, from where we will travel together by subway to Tokio Station. What I considered to be exaggerated decency turned out to be an ordinary pragmatic solution. Underground Tokio Station is a city in the city. It is the hub where the subway of two private companies, JR trains and high-speed shinkansen, intersects. It took us more than 20 minutes to get to our platform. I understood that meeting in a tangle of endless underground corridors and vestibules would not work well.

Rows of peacefully waiting passengers were formed in front of the wagons of our Shinkansen. Well, not the queue we're used to. Thin regular snakes, exactly according to the lines painted on the ground. Ubiquitous order and discipline in live. It took 7 minutes for the train to leave, but the doors on the wagons were still closed. It was the cleaning crews that completed the "sterilization" of the interior. "Ha, I'll catch them now, they can't make it," I thought with the mischief of our fellow man. At that, the door opened and the passengers began to board calmly. Yuji and I sat in the reserved places and I blinked discreetly at my watch. 14:00 departure time. In this, instead of the expected jerk, the train began to move north unnoticed. They got me again ...

Shinkansen literally means new line.

The 320-kilometer trip to Tsubame was reminiscent of the comfort of traveling by plane. But unlike the flight, it offered the opportunity to watch the surrounding countryside. The dense development gradually thinned until it was finally replaced by the countryside with countless rice fields. The more we moved north, the more the scenery reminded me of Slovakia. Valleys lined with mountains and lots of greenery everywhere. I always try to make the most of my time abroad, so in addition to watching the country, I overrun Yuji with a flurry of questions. As a pure technocrat, of course, I'm interested in shinkansens. I have learned that they have been operating in Japan since the 1960s. Realizing that steam locomotives were still common in our country at that time and that Japan was less than 20 years after the devastating end of the war, I did not understand. I was even unsuccessful with the fact that there are also faster trains in the world. Yuji patiently explained to me, and without any sign of comment, that contrary to short distances trains designated as a tourist attraction / Shanghai /, they are building a 1,500-kilometer route on which the Shinkansen will run at speeds in excess of 500 km / h. "It will take us about 7 more years," he added modestly.

Kataoka-san himself was waiting for us at the station in Tsubame. He greeted us with dignity and seated us in the equally dignified Toyota Crown Super Saloon V8 Model 95, which he drives himself. This is another nice feature of Japan. Who would expect a car fleet composed of the newest and most advanced cars will be surprised. The Japanese drive ordinary, often 20-year-old cars. However, their condition is reminiscent of the new ones. Always clean and quiet in perfect technical condition. This testifies not only to their technological sophistication, but also to their rational approach to life.

We started the visit at the local exhibition center. The prefecture of Niigata is known for its industrial production. It focuses mainly on metal production for households and agriculture. We went through the expositions of local companies. A great way to get to know this part of Japan. Of course, the Tamahagane, Tojiro and Global knives were also among the exhibits.

Tsubam Exhibition Center.

In the evening at sake and excellent Kirin beer, we covered a lot of topics. The common denominator was, of course, knives. Kataoka-san spoke with sincere respect for its competitors in the Tsubame-Sanjo area. He claimed to be like one family and helping each other. But the proverbial kidding also works between them. Despite the pleasant and relaxed atmosphere, I could not wait to enter the birthplace of the Tamahagan knives.

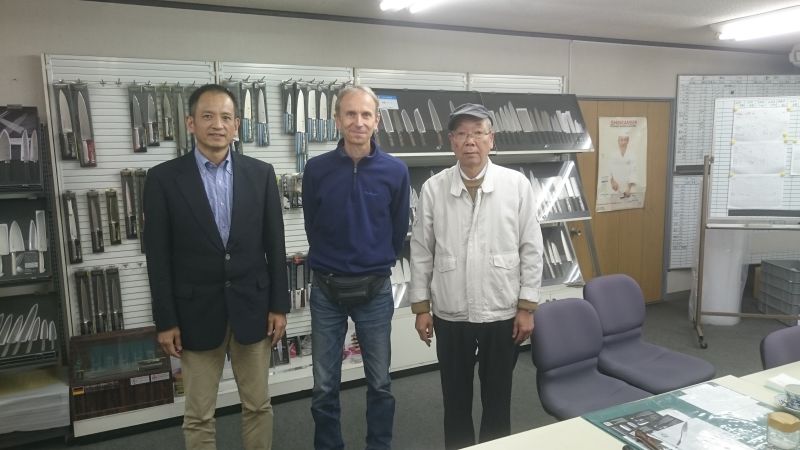

Yuji a Kataoka- san.

After a hearty Japanese breakfast, Kataoka-san was waiting for us in front of the hotel to take us to his kingdom. Right in the entrance warehouse, I was surprised by cartons with ceramic grinders from a competing company. The attentive eye of the owner immediately registered my weak hidden surprise. He said with a smile, "Mino can't catch up, so I'm helping him a little. It is important for him to supply these grinders, as his knives are excessively dull, "he added with a roar of laugh. I skilfully took advantage of the good mood of the owner and got permission to take photos directly in the production. It is not always a matter of course, so I appreciate this privilege immensely. I expressed my thanks and I add with one breath that the photos from the production will serve exclusively for my personal database, which of course I will keep.

We go through the individual stages of production, as they logically follow each other. Material storage, stamping, hardening, tempering, leveling, milling, welding, grinding, polishing, handle assembly, grinding, etching, inspection and packaging. The factory is clean and well organized. The machinery has a wide range. From those who already remember something to a modern laser welder. It is invested very rationally. What works remains in operation despite the existence of newer models. Again, a demonstration of the Japanese approach. I was very curious about the assembly of San, San Tsubame and San Kyoto handles. Since Kataoka-san considers it his know-how, he respectfully asked me not to photograph this process. I have to admit that this is a really sophisticated and very reliable and relatively quick way to fix the handle. & Nbsp;

At one of the cutters we meet Mr. Kataoku's son. So it is clear that the future of Tamahagane knives is guaranted. In addition to the Tamahagane brand, Kataoka-san also produces Brieto knives. However, they are intended mainly for the domestic market.

After a tour of the factory, we sit in the owner's office to answer my endless questions during a 3-hour interview. I was especially interested in how it can process steel VG-5 so that its final properties match the more expensive VG-10 . I quickly realized it was his favorite topic. He described to me how he had befriended the former president of the Takefu Steel Company, and he introduced him to this mystery. Subsequently, on the tables with the chemical composition of individual steels, he explained to me how the individual elements behave during processing and how their properties can be influenced.

Yuji, author and Kataoka-san in the showroom.

The combined cities of Tsubame and Sanjo / separated only by a common railway station / in Niigata Prefecture belong together with places like Seki , Tosa , Sakai and Takefu are among the most important knife centers in Japan. Well-known brands such as Tamahagane, Tojiro and Global are based here, which export their knives all over the world. In addition, they also produce knives for the domestic market. Therefore, the largest Japanese distributors are concentrated here. Their huge logistics warehouses alternate with countless rice fields. The area is separated from the sea coast by mountains with snow-capped peaks. Excellent tsunami protection, say the locals. I really liked this quiet place, so I'm glad I don't have to leave yet. There is a visit to Tojiro in front of me, but next time.

Tsubame Suburb in Niigata Prefecture.

Sign in

Sign in Registration

Registration