Product detail

Sakai Takayuki is one of the most respected brands in all of Japan. This is mainly due to their human potential. Getting masters with many years of experience and securing new generations to replace them is not easy at present. But Aoki Hamono manages to fulfill this difficult task, as evidenced by the strong demand for their products.

The company naturally likes to take on new challenges. Of course, it no longer has to prove that it is one of the top manufacturers of hand-forged traditional knives; its logo is a sufficient guarantee. But to show the same qualities with modern materials, this is a gage. Therefore, the company employs craftsmen who specialize in this area. They make blades from modern stainless steel, which they often simply call INOX. The Japanese "silver" Gingami 3 is especially popular.

However, the company's ambitions go even further. How about making a Japanese knife from the highest quality foreign steel? Where to get it? Well, in Sweden, of course, that's clear.

The history of the local steelworks Uddeholm began in 1668. Sufficient time to learn to produce the most sophisticated steel. Today, it is part of the Bohler-Uddeholm Group.

The choice fell on the super-fine AEB-L. It is characterized by a low content of sulfur and phosphorus and is therefore considered extremely pure. It has fine carbides, which contributes to the homogeneity of the structure. It therefore grinds very well. Compared to Japanese competitors, it has a lower carbon content and is therefore less fragile. The increased content of manganese and silicon gives it very good abrasion resistance. This, together with a hardness of 60 HRC, makes it the ideal steel for making blades.

The properties of this steel allow for a monolithic construction. The blade is therefore not layered, but is stamped from AEB-L sheet. Same as some special series of brands Kasumi or Mcusta-Zanmai / steel VG-10 /. A slight disadvantage of such a solution is the increased price, as the expensive core steel does not only form a middle part, but a complete blade. However the customer knows what he is paying for.

Everything else is strictly Japanese. Half tang construction, a ferrule from the genuine buffalo horn and an interesting hexagonal handle made of Japanese magnolia. Its lower part is round, so the grip is not only firm, but also pleasantly soft. The brand and the name of the series embossed in kanji characters on the blade cannot be missing.

The knives are intended mainly for professional chefs. They are therefore "Japanese" light, which chefs will appreciate during long shifts. Their name GRAND CHEF is therefore very appropriate.

2019 Copyright Roman Ulík, Nippon Knives, www.japonskenoze.sk all rights reserved.

Photos and texts are protected by copyright and their use is not possible without the author's consent.

About producer

Sword – a symbol of ancient Japan. It is no coincidence that it forms one of the imperial insignia. It is a Kusanagi sword and its core was also created by multiple folding and forging of the highest quality steel. Thanks to many generations of talented craftsmen, this proven method of producing hard and tough material has been preserved to this day. This is how knives were created that have no parallel in the world.

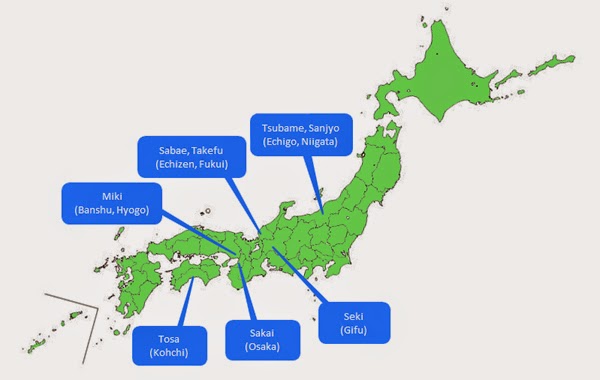

Sakai, or the city of knives, is today a western suburb of Osaka. The city experienced its greatest development in the 16th century, when it was one of the busiest commercial centers. The latest technologies from all over the world as well as different cultures met here. This helped the development of blacksmithing techniques, which had already reached a high level thanks to the production of traditional swords. The Portuguese brought the first rifles to the area and Sakai blacksmiths changed the production program. But since it was a period of peace, they mainly produced decorative rifles. With the boom in tobacco, they smoothly transitioned to the production of knives for cutting tobacco, but the mechanization of its processing resulted in another production change. Blacksmiths began to specialize in the production of kitchen knives. It was also influenced by the proximity of another important city - Kyoto. It is characterized by its culinary art, and the preparation of individual dishes requires special knives. Today, the majority of Japanese chefs use knives made in the city of Sakai.

Sakai has a slightly shorter history compared to Seki, but nowadays it is their meaning comparable. The difference is mainly in the production program. In Seki, the production of Western-style Japanese knives prevails, with a strong emphasis on export. Manufacturers in Sakai, on the other hand, specialize mainly in traditional Eastern-type knives. Their clientele consists mainly of Japanese professional chefs.

Mr. Takayuki became famous for consolidating the Sakai blacksmiths in 1946. He provided them with production facilities and tools and thus founded the Sakai Takayuki brand. It is currently being looked after by the 3rd generation of this family. The brand is owned by Aoki Hamono, which in 2006 won the prestigious Sakai Wazashu award for the skill of local manufacturers.

The potential of the Aoki Hamono company lies in key personnel positions, which are blacksmith and grinder. Masters with high awards and with experience exceeding 50 years in some cases work here.

Keijiro Doi - blacksmith

At the age of 19, he took the place of his father, a prominent blacksmith, in the workshop. In 1987, he was certified by the Ministry of International Trade and Industry as a Blacksmith Master. In 1997, he received the Green Paulownia Leaves award.

Yukinori Oda – grinder

He is a holder of the Sacred Treasure order, Silver Rays. Already at the age of 20, he became a master. He sticks to his motto: "The sharpness of a good knife is 100%." However, the role of the grinder is to increase it to 120%."

Suogo Yamatsuka - blacksmith

He constantly pushes the boundaries of perfection. He specializes in Gingami 3 anti-corrosion steel.

Hirotsugu Tosa – grinder

He was born in 1948 and trained as a grinder at the age of 18. In 1991 he achieved the title Sharpener Master. He knows no compromises in his work because he is constantly thinking about the users of his knives.

Itso Doi - Blacksmith

Son of Master Keijiro. It represents the third generation of the clan. He is best placed to preserve this championship for generations to come.

Mitsuo Yamatsuka – grinder

In 1999, he received the Japanese Traditional Craftmanship certificate. It is a guarantee that a traditionally forged knife will acquire "Sakai" sharpness.

Due to the handmade production and the huge interest among professionals in Sakai knives, it is quite difficult to obtain at least a few pieces. Our efforts and patience finally brought us the honor of introducing you to products in which the soul of their makers resides. Welcome to Sakai!

Video from the workshop

©2019 Copyright Roman Ulík, Nippon Knives, www.japonskenoze.sk all rights reserved.

Photos and texts are protected by copyright law and their use without the author's consent is not possible.

Sign in

Sign in Registration

Registration