Product detail

SAKON RYUGA sashimi knives belong to the practical Hokiyama Cutlery product line. From the point of view of the materials used as well as the design itself, they represent the best for professional sushi masters. The knives have been designed and manufactured so that the master does not waste his precious time taking too much care of his tool.

Yanagiba means willow leaf in translation. They are called sashimi knives, whose long and slender blade resembles a weeping willow leaf. The real yanagiba has a one-sided grinder. Thanks to it, you have better control over the cut, long slices of meat are more symmetrical and you can cut even the thinnest slice of meat, fish or vegetables. Anyone who has worked with such a knife will have a hard time returning to double-sided grinding.

Let's take a closer look at why SAKON RYUGA knives belong to the absolute top in the sashimi knife class. Let´s start

with blade material. Most quality sashimi knives use Yasuki Hagane / Shirogami, Aogami and Aogami Super /. These are very hard steels with a high carbon content. This traditional Japanese material reaches a hardness of 60 to 63 HRC. However, SAKON RYUGA blades are made of SRS15 high-speed tool steel. It is a special alloy steel not only with a high carbon content / over 2% /, but also with admixtures of tungsten, cobalt, titanium, vanadium, molybdenum and chromium. By process

with blade material. Most quality sashimi knives use Yasuki Hagane / Shirogami, Aogami and Aogami Super /. These are very hard steels with a high carbon content. This traditional Japanese material reaches a hardness of 60 to 63 HRC. However, SAKON RYUGA blades are made of SRS15 high-speed tool steel. It is a special alloy steel not only with a high carbon content / over 2% /, but also with admixtures of tungsten, cobalt, titanium, vanadium, molybdenum and chromium. By process

Powder metallurgy ensures an ideal microstructure, which results in strong, durable and tough steel with a hardness of 64 - 65 HRC. In addition, thanks to chromium, titanium and cobalt, the steel does not oxidize and has anti-corrosion properties. This means that the blade does not need to be treated and its blade will last a very long time. Yanagiba of course has a layered blade and an outer layer of so-called "support steel" is made of softer stainless steel SUS405.

Powder metallurgy ensures an ideal microstructure, which results in strong, durable and tough steel with a hardness of 64 - 65 HRC. In addition, thanks to chromium, titanium and cobalt, the steel does not oxidize and has anti-corrosion properties. This means that the blade does not need to be treated and its blade will last a very long time. Yanagiba of course has a layered blade and an outer layer of so-called "support steel" is made of softer stainless steel SUS405.

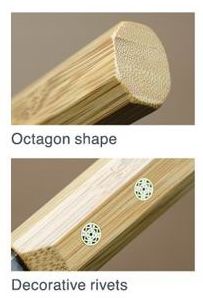

The highest class of sashimi knives comes almost exclusively with octagonal handles. Yanagiba SAKON RYUGA has it made of laminated bamboo. Bamboo lamination takes place in a factory producing bamboo steering wheel parts for luxury Japanese cars. This technology achieves perfect moisture resistance. The two rivets ensuring a firm connection between the handle and the blade and also have a decorative character. Every detail was taken into account when designing SAKON RYUGA knives. Even so, the exceptional blade is completed by an etched image of a Japanese mythical dragon, which can be engraved on request. It includes an elegant bamboo saya that reliably prevents injury while moving the knife.

We invite you to Nippon Knives to experience the feeling of the most famous sushi master.

©2010-2018 Copyright Roman Ulík, Nippon Knives, www.japonskenoze.sk all rights reserved.

Photographs and texts are protected by copyright and their use is not possible without the author's consent.

About producer

Tosa is the ancient name of today's Kochi Prefecture, which is located in the southern part of the island of Shikoku. The north of the prefecture is made up of inhospitable mountains, which towards the south pass into a fertile plain filled with countless rice fields. They are protected from possible tsunami waves by barriers built on the beaches of the Pacific Ocean. Connoisseurs of Japanese blacksmithing will not call this area anything other than Tosa.

For more than 800 years, the interlaced steel made famous by samurai swords has been forged in Tosa. It can be said that this area has become a kind of "open-air museum" of traditional blacksmithing. You will find small workshops scattered here, in which individual family generations create gems that are incomprehensible to us. It is almost a rule that father and son work in the workshop to ensure the continuity of the tradition. All kinds of blades are made here, from agricultural tools to rare knives, but in a diametrically different way than in the Seki, Sakai, or Tsubame/Sanjo areas. Knives intended for decoration were never produced here, but durable work tools. That is why knives from Tosa are sought after by connoisseurs all over the world.

Since 1919, the Hokiyama Cutlery company has been among the pioneers in improving the traditional production of kitchen knives. In accordance with the motto "the good must be preserved and, if possible, also improved", Shinsuke Hokiyama created 3 lines in his company: traditional, practical and innovative.

The traditional line /Tosa-Ichi/ consists of hand-forged blades from such masters as Takeo Murata. It is a layered steel, the core of which is high-carbon shirogami or aogami type steel. Hitachi Blue Super is used for the best pieces. The blades are most often in the unpolished form of kurouchi. Knives require care, as this material is not anti-corrosive. The practical line /Sakon/ is a symbiosis of traditional production procedures with modern materials and design. In addition to high-carbon steel, very hard powder tool steel and damascene steel are also used. Emphasis is placed on precisely processed and ergonomically tuned handles. The innovative line /Mugen/ is the pride of Hokiyama Cutlery. It adopts advances from other fields into the production of its knives. These are mainly self-sharpening knives SAKON+ with the patented Vee-Tech technology taken from the aviation and space industry.

Friendly relations with the owner of Hokiyama Cutlery, Mr. Shinsuke Hokiyama, enabled us to gradually bring you the most interesting knives from the legendary Tosa region.

©2010-2018 Copyright Roman Ulík, Nippon Knives, www.japonskenoze.sk all rights reserved.

Photos and texts are protected by copyright law and their use without the author's consent is not possible.

Sign in

Sign in Registration

Registration